The Ultimate Guide to Pad Printing

Pad printing is the process of printing a two-dimensional image on a complex three-dimensional item. Common in the medical, aerospace, automotive, appliance, clothing, promotional, toy, and industrial printing sectors, pad printing has grown in popularity over the last 50 years, proving itself more versatile than alternatives like screen printing and hot stamping. With the pad printing process, detailed images can be printed on irregular surfaces and complicated substrates.

What Is Pad Printing?

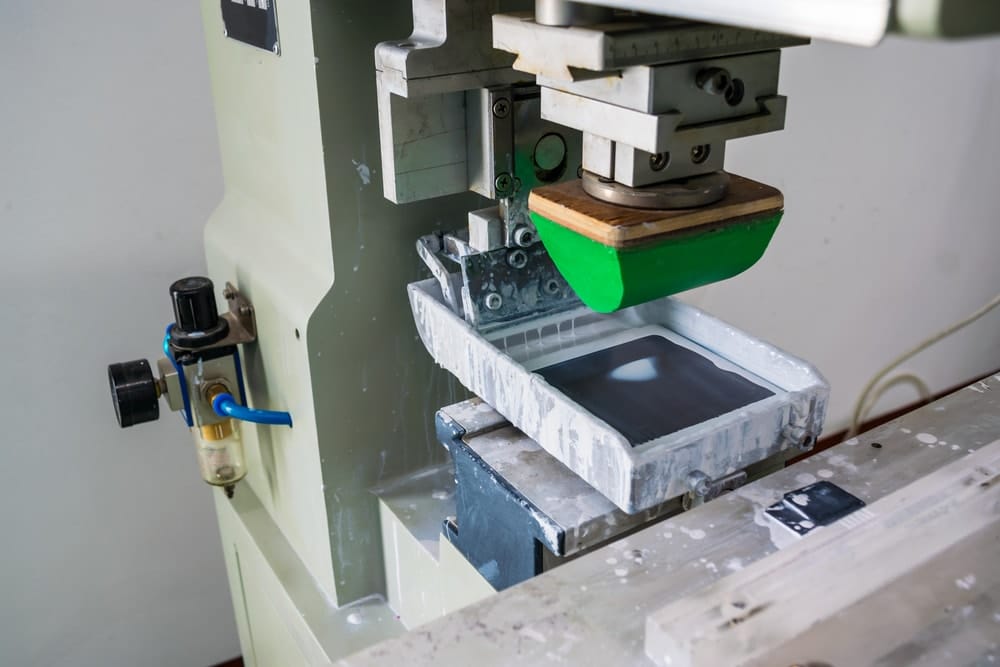

In pad printing, a silicone pad transfers an engraved image from a 2D printing plate (or cliché) to a 3D object. Also called indirect offset or gravure printing, this process involves the pad picking up ink from the etching and pressing it into the object. The pads are typically round or rectangular, though the shape and size depend upon the project.

Pad printing services offer an efficient method for achieving high-quality images on unusually shaped substrates, such as curved, hollow, spherical, cylindrical, angled, and textured items on a wide variety of substates.

Pad Printing Components

A pad printing machine is relatively simple, and emerging technology continues to streamline the process. There are three essential components to a pad printing machine:

- Pad: The pad is used to transfer the image onto the 3D object. Different printing applications require different pads—the hardness of the silicone, as well as the shape and size of the pad, will vary depending on the complexity of the image and the dimensions of the object.

- Ink cup: Ink is deposited on the 2D plate via the ink cup, which is comprised of a ring and a cup. The ring is usually made of ceramic, metal, or plastic. Ceramic is typically the preferred choice because it’s less likely to leave scratches on the plate. The ink is left only in the etched part of the plate, so the pad can pick it up for the next step in the printing process.

- Printing plate: The image to be printed is etched on the plate via a photopolymer or laser process. In photopolymer plate-making, a photosensitive plate is exposed to UV light to create the image. Although it is time-consuming, photopolymer plate-making is the most cost-effective option. The faster option is laser plate-making, which uses a carbon dioxide or fiber laser to create the image. Its computerized nature delivers accurate, replicable results.

How Does Pad Printing Work?

Pad printing started to grow in popularity in the 1970s, though there is historical evidence of the indirect offset printing technique dating back 200 years. This is how pad printing machines work today:

- The photopolymer or laser plate-making process etches a plate with the desired image.

- The ink cup moves over and fills the engraved plate with ink.

- The cup is removed, taking the excess ink with it and exposing the ink-filled etching.

- The pad is pressed onto the plate, and the ink is transferred from the artwork onto the silicone pad. As the pad moves away from the plate, the ink cup moves over the plate again, preparing to repeat the process.

- Meanwhile, the printing pad presses onto the object, creating the printed product.

This pad printing process repeats until the production run is complete.

Ink adhesion is the number one challenge in the pad printing industry since permanent ink adhesion is necessary. The solutions often require knowledge of proper ink selection, surface tension and energy and pretreatment and post treatment solutions. Proper post-curing processes must be applied, which often require 72 hours or more for typical non-UV curing processes and UV LED curing of 24 hours or more, using air blowers to aid transfer efficiency and following ink manufacturers’ drying and curing recommendations.

For certain industries such as medical and aerospace bring on additional challenges related to quality, tolerances, safety, traceability and regulatory requirements.

Pad Printing vs Screen Printing

Choosing between pad printing services and screen printing depends on the shape of the part, the level of detail required, and the production volume.

- Surface Compatibility: Pad printing works well on irregular, textured, or curved surfaces. The silicone pad can adapt to complex shapes, making it suitable for items like buttons, medical parts, or promotional products. Screen printing is better suited to flat or slightly curved surfaces, such as panels, signs, or flat plastic sheets.

- Ink Transfer and Detail: Pad printing allows for fine lines and small graphics to be printed clearly. It’s a practical solution for items that require precision and small-scale artwork. Screen printing typically lays down a thicker layer of ink, which can be helpful for bold designs and high-opacity prints, but it may not match the fine resolution of pad printing.

- Production Volume and Speed: For large batches of flat items, screen printing may offer a faster throughput. Pad printing is often more efficient for medium runs or when dealing with components that vary in shape or material.

- Cost and Setup: Pad printing often has a lower setup cost, especially for short runs. Screen printing can involve more preparation time and higher material usage, which may raise costs for smaller quantities.

- Durability and Finish: Both methods provide strong adhesion when paired with the right ink and surface preparation. Pad printing is commonly used for items requiring durable marking under repeated use, such as keyboard keys or medical tools.

Each method has practical strengths. Pad printing provides flexibility for complex surfaces, while screen printing delivers speed and ink density on simpler shapes.

The Benefits of Pad Printing

Although it is generally more expensive than screen printing, pad printing offers enough advantages for many applications that the results outweigh the cost. These are the main benefits of choosing pad printing over other methods:

- Exceptional image clarity and resolution

- Prints on unusually shaped and irregular objects as well as flat surfaces

- Produces precise, repeatable results throughout large and small production runs

- Silicone pads and image plates are customizable for every project

- Low setup costs

- Space-efficient equipment

- Wide selection of substrate dimensions and materials, including sensitive or delicate substrates

- Ability to print more than one image on a product at a time

- Various ink compositions: one-component ink for thermoplastics and two-component ink (ink mixed with a hardening chemical) for objects that will experience chemical or high-stress exposure

Pad Printing Applications

Companies in many industries rely on pad printing for sharp, durable images and text on critical equipment. Whether you need to print aesthetically pleasing graphics, important labeling, or user information, pad printing can provide the detailed results you’re looking for on objects of any shape and material.

-

Medical

The medical industry uses pad printing to print essential information on minimally-invasive devices, syringes, valves, surgical instruments, and more. These items must be manufactured and printed under sanitary conditions. At Pad Printing Technology, we maintain an ISO Class 8 Clean Room for these purposes. This room meets ISO 14644-1:2015 cleanliness requirements for contaminant-free printing.

-

Aerospace

Printed components for the aerospace industry must be clear, durable, accurate, and compliant with strict industry regulations. For over 35 years, Pad Printing Technology has delivered superior laser marking and pad printing services to our partners in the aerospace industry. We print switches, buttons, coding, identification labels, regulatory information, panel and control marking, brand names, logos, and more.

-

Automotive

Printed parts for the automotive industry must be long-lasting, legible, and regulation-compliant. We can pad print on all sorts of materials, including painted and anodized metals, stainless steel, fiberglass, plastics, wood, and glass. Decorative and essential printing may include buttons, panels, tools, and gauges. Our ISO 9001:2015 certified facility guarantees the highest standards for product quality, employee safety, and customer satisfaction.

-

Electronics

Because aesthetics have become increasingly crucial to attracting consumer attention, designing and printing consumer electronics are more important than ever. Pad Printing Technology offers pad printing and laser marking for a wide array of electronic components. We can multi-hit pad print images for greater ink opacity and durability, or we can pad print a UV clear coat over them.

-

Industrial

For other industrial printing applications, we use our closed-cup printers, which can quickly and consistently print designs with tight tolerances. These printers allow us to change images with minimal machine downtime for a more cost-effective printing run. We pass these savings on to our customers.

Expert Pad Printing Services from Pad Printing Technology

At Pad Printing Technology, we specialize in 3D computer-aided designing, printing, and prototyping. We deliver pad printing services and laser marking services to customers in the aerospace, automotive, medical, electronics, and commercial/industrial markets. We continue to invest in new technology and systems to ensure we provide the highest quality printing possible.

Since 1994, we’ve been providing high-quality printing services for a wide range of materials, including plastics, metal, wood, glass, composites, Kraton, paper, rubber, leather, nylon, and foam. Our dedicated customer care team can offer expert guidance on design, material selection, and more. Contact us to get started on your printing project.