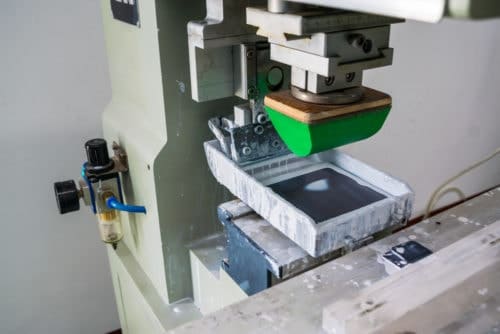

We use cutting-edge technology, such as our trusty pad printer, with features that make our results stand out. Apart from that, we’re committed to delivering services that will meet or exceed your expectations to ensure you receive the best outcomes.

Understanding Pad Printing

Pad printing, also known as tampography, is printing a 2D image on a 3D object. It can print exquisitely-detailed photos consistently. It’s an indirect photogravure process, transferring images using heat to the medium with a silicone pad on the pad printer machine.

Due to its consistent results, it has become an essential printing process in the printing world. Moreover, it has many other benefits due to the silicone pad since it’s the main feature for achieving successful pad printing.

Exceptional Contract Pad Printing

We use a specialized contract pad printer that can print anything you want. It means we provide a fully-customizable service where we can print logos, artwork, etc. But apart from pad printing, we also offer laser marking and etching services. Generally, it allows us to work with a variety of industries.

- Medical

- Aerospace

- Automotive

- Commercial

- Industrial

We have partnered and formed a strong relationship with our customers from the industries mentioned. That’s why we have a solid customer base, and they require our contract pad printing services to fulfill large and small orders quickly and efficiently.

Common Applications of Pad Printing

Pad printing is a prevalent method compared to other printing processes. Our customers choose it due to its versatility and capability to produce consistent results. Plus, we can use it for different types of applications.

Below are some of the more common applications for which pad printing is used:

- Labels

- Medical Devices

- Packaging

- Promotional Items

- Tools & Parts Marking

- Electronic Components

- Toys & Games

Some Advantages of Pad Printing

Since pad printing provides incredible results, industries choose it over other printing methods. Plus, it offers a slew of advantages that you should consider.

Benefits of pad printing:

- The silicone pad allows printing on irregular surfaces

- Efficiently transfer designs on complex geometries or mediums

- Prints on three-dimensional parts

- Can print on embossed or etched surfaces

- The ability to print on various substrates, such as glass, metal, etc.

- The use of different inks for surfaces that require high resistance against chemicals

Choose Us for All Your Contract Pad Printing Needs

If you’re looking for a reliable service provider of pad printing, then Pad Printing Technology is the best option. We can take care of your contract pad printing needs. Whatever your requirements or specifications, we can handle it.

So if you have any concerns or questions, contact us today or request a quote. We’re here to find a solution to your printing needs immediately.